Life of Tempered glass

Physical tempering is to heat and quench the glass, changing the structure between the molecules inside the glass; chemical tempering is to exchange the molecular structure of the glass surface at high temperature; both methods are permanent changes to the glass material. Therefore, unless there is high temperature and strong chemical action, the characteristics of the tempering will not change with time under normal use.

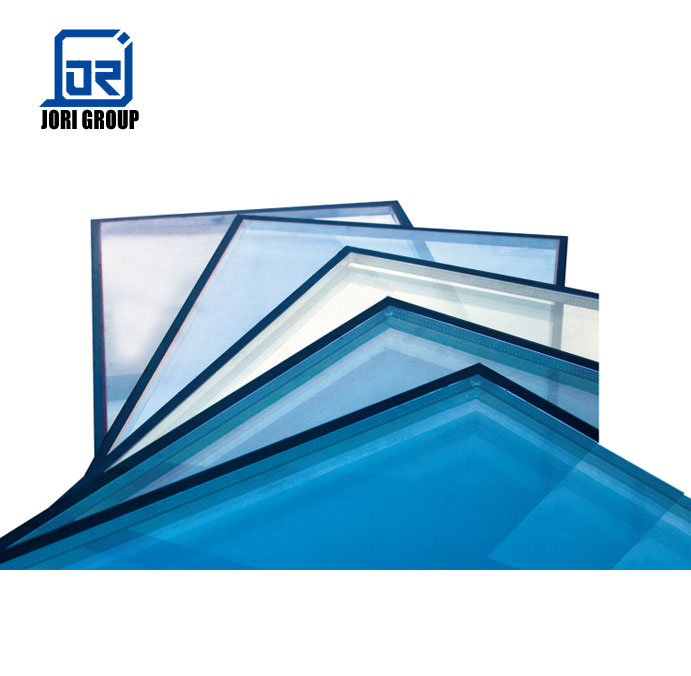

Life of Insulated glass

In the insulating glass national standard GB/T11944-2012, the reference convention for the life of insulating glass was first proposed, and the concept of “expected life of insulating glass should be greater than 15 years” was proposed. In fact, the life of the insulating glass has a close relationship with the selection and processing technology of the insulating glass material, and is also affected by many factors such as the composition of the insulating glass plate and the use environment, which is difficult to quantify. For insulating glass that has been installed on a wall, the simpler measure is actually measuring the dew point or spacer air humidity.

Life of LOW-E glass

The life of LOW-E glass depends on the life of the hollow sealing system. We know that the main constituent materials of the LOW-E film layer are metals, alloys, metal oxides and metal nitrides. Metal nitrides are generally used as a protective layer in a film structure, and their properties are very stable. The metal oxide and alloy layers generally connect the silver layer and the protective layer as a dielectric layer in the film layer, and the properties thereof are also relatively stable. The silver layer in LOW-E is relatively active, but its oxidation is conditional and requires water vapor. Therefore, as long as the insulating glass does not fail, it is basically unnecessary to separately consider the life of the Low-E film layer.

Life of Laminated glass

PVB and SGP laminated glass, which is commonly used as a door or window or curtain wall, has much better aging resistance. The most typical failure of laminated glass PVB and SGP is the opening of the glue. Opening the glue means that the glass and the spacer layer are disengaged, losing the safety characteristics of the laminated glass. Regarding the life of PVB and SGP laminated glass, there are currently no relevant standards and specifications in China. At present, domestic glass processing enterprises generally give 5-7 years product warranty period with reference to foreign PVB and SGP supplier related materials.