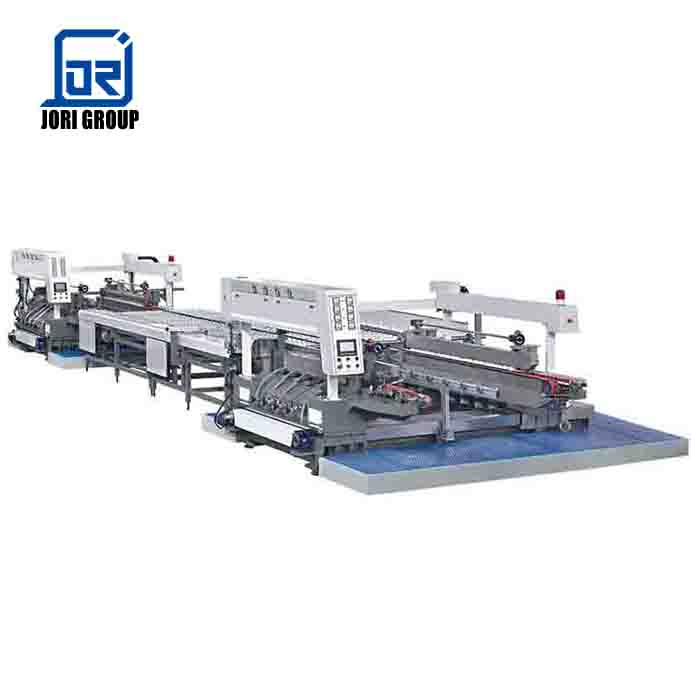

This line is composed with 1# straight line double edger, rotating working table (linear rolling type and L type available), 2# straight line double edger can include safety corner. It can be assembled with automatic glass loading table, cleaning machine and automatic unloading table to make a full set of automatic production line. Glass is loading by automatic loading table to transmission table which transmit it to 1# straight line double edger for automatic position grinding. Glass sheet getting into rotating working table to turn around 90 degree and arrive 2# straight line double edger machine for secondary automatic position grinding then getting into cleaning machine. Automatic unloading table will put glass sheet on the glass shelf after cleaning and drying. This production line has the features are high precision, easy maintenance, convenient and quick adjustment, simple operation, high automatic level and labor cost saving. Glass processing from loading, grinding, rotating, cleaning to unloading are finished by one time.

| Minimum. processing size | 250X250mm |

|---|---|

| Maximum. processing size | 2500x2000mm (can design of your size to special mad |

| Thickness of Glass | 3-12mm |

| Processing Speed | 1-6m/min(or 3-12m/min) |

| Single side maximum grinding | 3mm |

| Height of Working Table | 930mm±30mm |

| Maximum bottom margin grinding | 4200mmx2500mm |

| Maximum arris grinding | 3mm |

| External Dimensions | 16500X4600x2500mm |

| Pneumatic Working Pressure | 0.7Map |

| Total Power | 50KW |

| Gross Weight | 12000kg |

| Product Keywords | Glass Pencil Double Edger Processing Line with Low price |