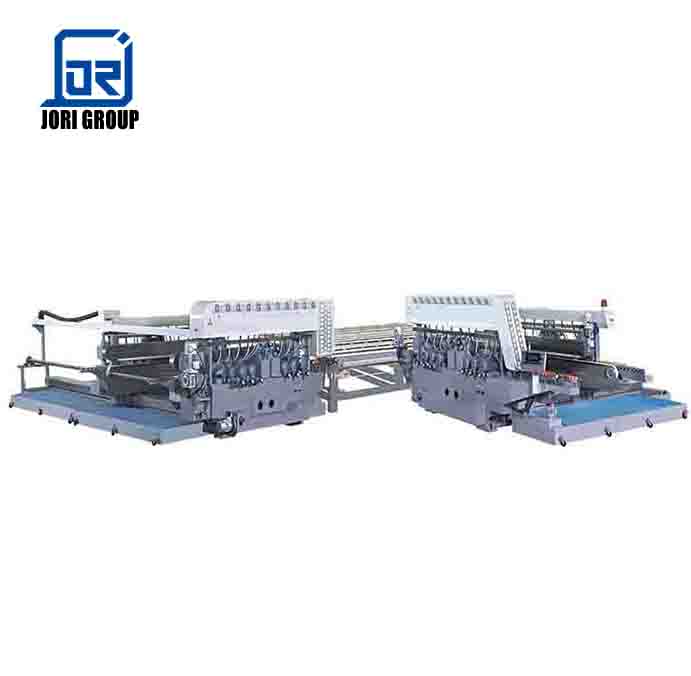

This line is composed with 1# straight line double edger, transfer table (straight type、 L type & suction cup type are also available), 2# straight line double edger can include safety corner. It can be connected with automatic glass loading table, washing machine and automatic unloading table to make a full set of automatic production line. Glass is loading by automatic loading table to transmission table which transmit it to 1# straight line double edger for automatic position grinding . Glass sheet getting into rotating working table to turn around 90 degree and arrive 2# straight line double edger machine for secondary and automatic position grinding then getting into washing machine. Automatic unloading table will put glass sheet on the glass shelf after cleaning and drying. This production line has the features are high precision, easy maintenance, convenient and quick adjustment, simple operation, high automatic level and labor cost saving. Glass processing from loading, grinding, rotating, washing to unloading are finished by one time. According to customer’s space, the production line can be straight type、L type & U type. The glass double edger production line is suitable for processing the craft glass、building door & window glass、solar glass & electric glass that kind of automatic processing line.

| Min glass size | 350x350mm |

|---|---|

| Glass thickness | 3~30mm |

| Glass processing speed | 1~12m/min |

| Total power | 107.7KW |

| Total weight | About 12T |

| Max glass size | 4200mmx2500mm can special made) |

| Max base grinding | 5mm |

| Max chamfer grinding | 3mm |

| Pneumatic working pressure | 0.7Mpa |

| Moving speed | 15m/min |

| Overall size | 14000x9200x2300mm |

| Product Keywords | 2018 New Glass Double Edger Processing Line edge polishing line |