Maintenance is an important part of the process of using glass machinery, and it is also an important guarantee for the normal and efficient operation of glass machinery. However, according to many customers who purchase glass machinery, the abnormality of the glass mechanical parts is often caused by the maintenance, which results in a reduction in the service life of the glass machine.

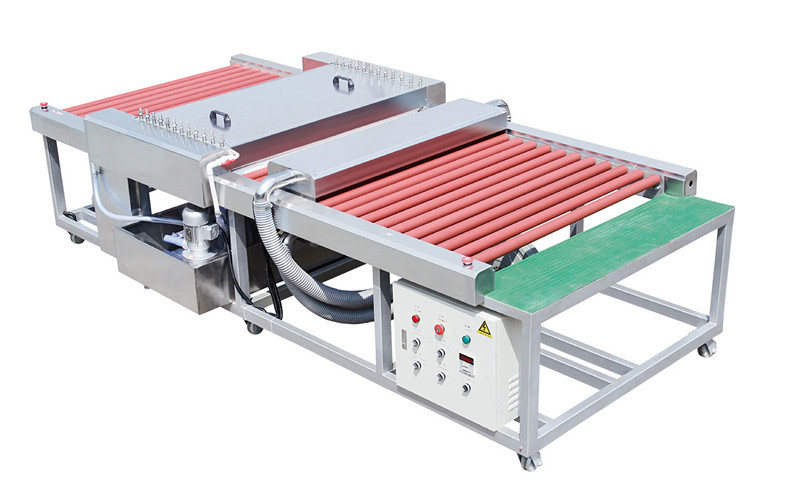

Taking a glass washer as an example. The daily maintenance of the glass washer is a very important task. Usually, the transmission part of the machine, the water circulation system, the electrical system and the air path system are often tested. If you encounter an emergency, you must immediately press the emergency stop button to check.

1)Delivery part maintenance

The maintenance of the transmission part is worth paying attention in order to ensure the smooth operation of the conveyor system.

2)Maintenance of water circulation system

The water circulation system is related to the quality of the cleaning glass, so it is recommended to replace the pure water in the water tank every day. The tank and filter unit are cleaned every week. In the cleaning process sheet, the nozzle can be inspected through the small hole above the lid of the water tank. If there is a blockage, it should be stopped immediately, then the nozzle should be removed, and the nozzle is confirmed to work after the normal operation of the nozzle.

Now It’s Your Turn

I hoped you enjoyed my detailed information for starting a business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.